Torque limiter for gearboxes

Up to 2,800 Nm of torque and 65 mm bore diameters.

Safety coupling to be mounted between the motor and gearbox with flange B5 spacer. Available in sliding (DF) and disengage versions (DSS/F/SG-PR-V). The location of the limiter between the motor and gearbox requires a smaller size of device with also reduces costs.

- Safety joint made of steel, aluminum spacer completely machined;

- Anti-corrosion treatment standard phosphate on the torque limiter;

- Compact solution;

- The device worked for IEC motors and gears;

- Protection in both directions of rotation;

- Disengaging instant to overcome the torque set;

- Simple calibration system with H fee for an immediate calibration of the device.

- The device is already configured and ready to use;

- Possibility of friction rings with different performance in the case of model slip;

- Free rotation backlash free balls model according to ATEX conformity;

- Possibility of surface treatments for corrosion-specific needs.

- Conveyor belts;

- Packing machines;

- Packaging machines;

- Systems for handling and positioning.

- Best simplicity and sensitivity to integrated solutions in reducing them;

- Protect the gear motor from accidental collisions or impacts of the product limit;

- Reduce downtime in the event of overload;

- Absorb starting torque without disconnecting the transmission.

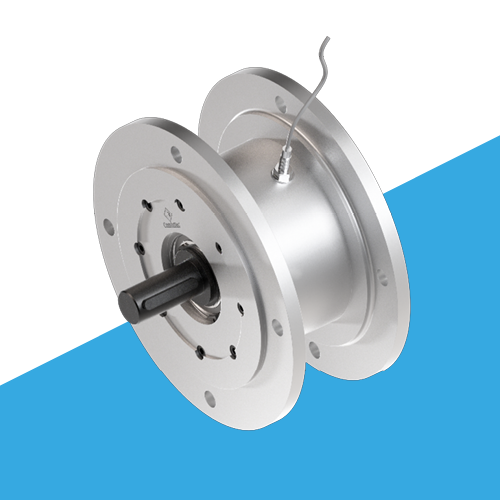

Balls solution, torsional backlash free "DSS/F/SG/PR-V"

- Balls solution, torsional backlash free in negative version, maintenance free;

- Instant disengagement between driving and driven parts in the event of overload;

- Available with single point (360°) engagement;

- Complete solution with connecting flanges in aluminum for IEC B5 motors;

- Inductive sensor integrated for monitoring the overload;

- Torque range: 2-720 Nm; bore/shaft max ø48 mm.

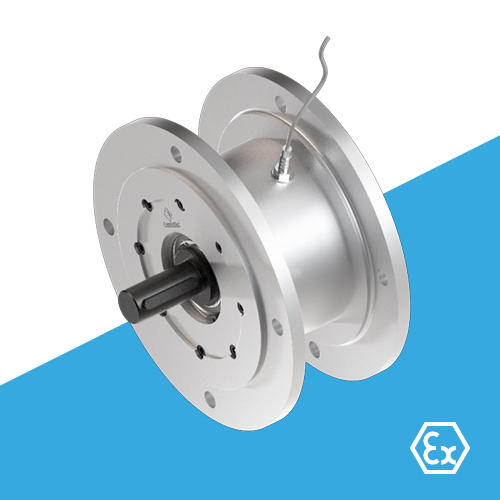

Balls solution, free rotation torsional backlash free model "DSS/SG/RF/PR-V"

- Balls solution, free rotation torsional backlash free model, maintenance free;

- Instant disengagement between driving and driven parts in the event of overload;

- ATEX conformity: II 2 G Ex II B T5 Gb -15°≤Ta≤+80°C;

- Complete solution with connecting flanges in aluminum for IEC B5 motors;

- Inductive sensor, integrated for monitoring the overload;

- Torque range: 2-1.300; bore/shaft max ø65 mm.

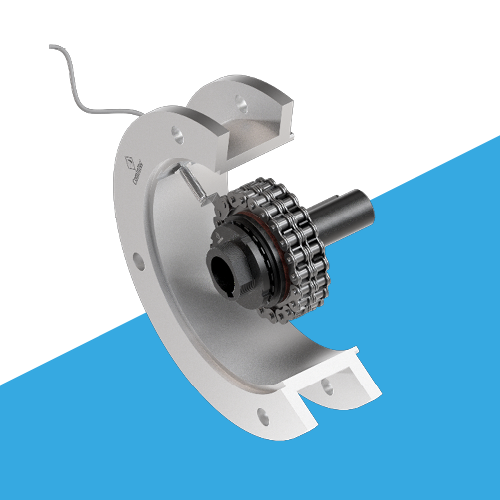

Friction model version with chain coupling for gearboxes "DF/TAC/PR-V"

- Compact and economic solution;

- Sliding of the driving part to overcome the torque calibration without disconnecting the transmission;

- Silent intervention and vibration-free;

- Complete solution with connecting flanges in aluminum for IEC B5 motors;

- Possibility of integration of an inductive sensor for monitoring the overload (DF/TAC/PR-V/S);

- Torque range: 1-1200 Nm; bore/shaft max: ø55 mm.

Friction model version "DF/PR" and "DF/TAC/PR"

- Possibility of friction on rings with diff erent performance for specifi c needs;

- Specifi cally designed for installation on on hollow output shaft gearboxes;

- Available complete with transmission component fully turned and fitted;

- Available with radial nut (…/GR) statically balanced;

- Model for gearboxes with a chain coupling, suitable for connections of coaxial shafts (DF/TAC/PR);

- Torque range: 1-2,600 Nm; max shaft: ø55 mm; max bore: ø65 mm.

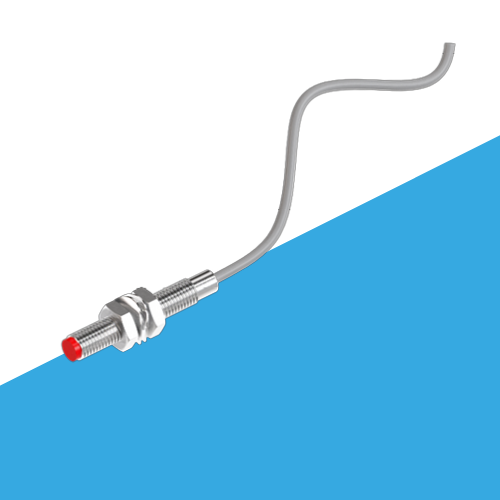

Proximity sensor "PRX"

- Standard version: Stainless steel cover with protection level IP67 DIN 40050;

- Electric contact: 7 ÷ 30 VdC. – Frequency: 4 KHz; Absorption ≤ 10 mA (Max 200mA);

- Output: NPN (N.O.-N.C.) – PNP (N.O.-N.C.);

- Operating distance: max 1,5 mm;

- Cable length: 2 m (3×0,2);

- Operation temperature range from -25°C to + 70°C;

- Available ATEX model (PR-EX).