Variable speed pulleys and motor slide bases

The expandable-disc pulleys (divided into two large families) are the most simple and economic solution for changing rapidly and continuously the rotation speed of two shaft, without having to stop the transmission.

- Good reliability;

- Wide selection;

- Easy installation;

- Highly accurate manufacturing;

- Competitive pricing without sacrificing quality;

- “Made in Italy” with certified quality.

- Variable centre distance: Consisting of two plates sliding symmetrically on a hub, transmits motion to a “fixed” driven pulley with variation ratios up to 1:3.5, by varying the distance between the centres of the two pulleys.

- Fixed centre distance: Consists of a pair of pulleys, both with a single mobile disc that makes it possible to vary the speed with a ratio of up to 1:12,3 by varying of the handwheel on the driving pulley.

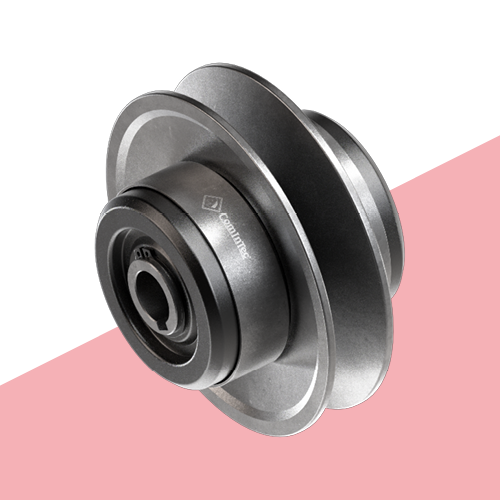

Model with self-lubricating round hub and galvanized plates "VAR.D.E.A.C./MTZ"

- Discs with anticorrosive galvanizing treatment;

- Self-lubricating round hub, maintenance-free;

- Very silent during operation work;

- Helical springs fully protected suitable for dusty environment;

- Suitable for high power;

- Max ratio 1:3,4 – max power 18,5 Kw.

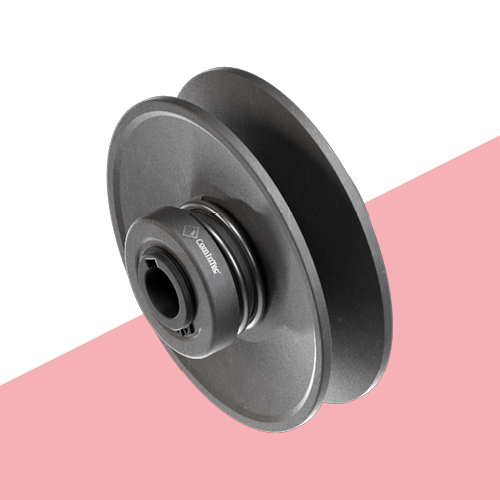

Model with round hub end helical springs "VAR.D.E.A.C./MTE"

- Discs with phosphate treatment;

- Self-lubricating round hub, maintenance-free;

- Partially covered helical springs;

- Compact model;

- Economic model;

- Max ratio 1:3,5 – max power 4 Kw.

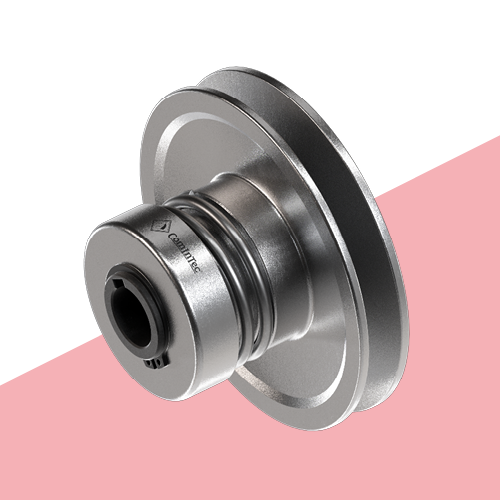

Model with mono-expandable disc, compact series "VAR.D.E.A.C./CAMPACT"

- Pulley mono-expandable with helical spring;

- Discs with anticorrosive galvanizing treatment;

- Self-lubricating round hub, maintenance-free;

- Suitable for normal trapezoidal small belts (17×11 max);

- Compact model;

- Max ratio 1:2,5 – max power 1,5 Kw.

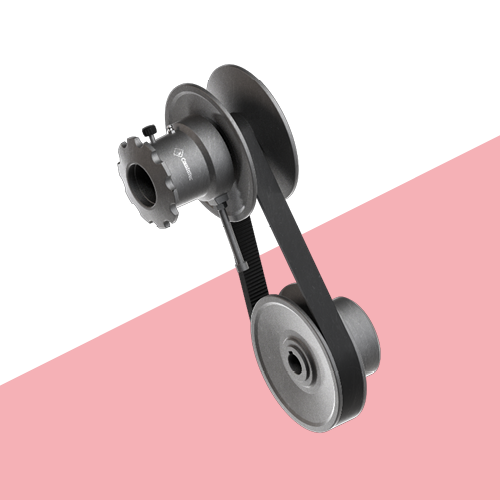

Model with round hub end helical springs "VAR.D.E.A.C./TE/IF"

- Self-lubricating round hub, maintenance-free;

- Couple of mono-expandable pulleys with a phosphating treatment on the disc;

- Disc Sliding Adjustment by handwheel;

- Max variation Ratio 1:12,3;

- Self-aligning during the variation of the speed;

- Max ratio 1:12,3 – max power 18,5 Kw.

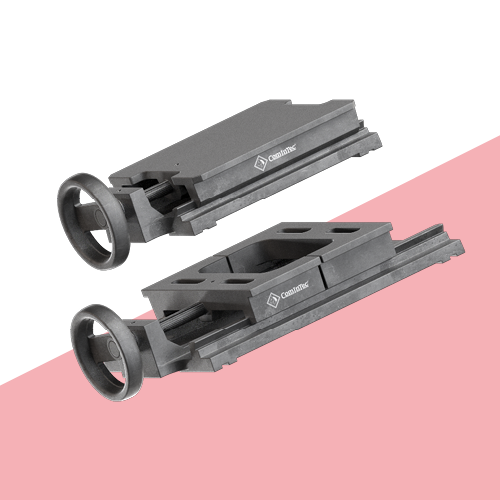

Die casting iron motor slide base "PMG"

- Made in die casting iron;

- Maximum rigidity and stability;

- Available with single or double sliding plate;

- Equipped with a handwheel for easy adjustment;

- Double sliding plate model already drilled ready for motor assembly;

- Available for IEC motors 56A – 180L.

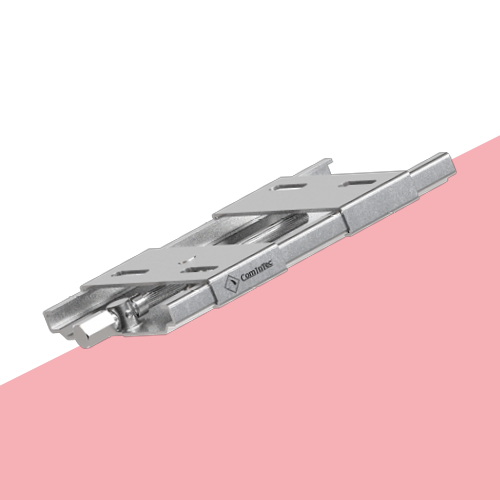

Sheet steel motor slide base "PML"

- Made in galvanized sheet steel;

- Galvanizing treatment after bending and machining to avoid oxidations on the elements;

- Assembly aligned to assure maximum sliding and avoid deformations;

- Completely drilled model for quick installation and motor assembly;

- Excellent price/performance ratio;

- Available for IEC motors 56A – 180L.