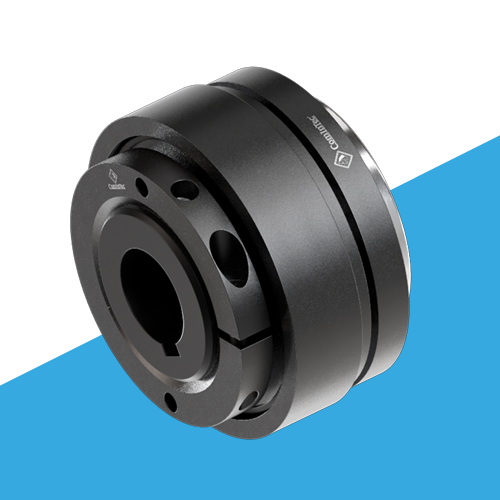

Backlash free torque limiter

Up to 1,200 Nm of torque and 65 mm bore diameters.

A ball safety coupling with high technology and precision. Provides backlash free transmission of motion with high sensitivity of reaction and an immediate release without peak load prior to release. The device can be adjusted by changing the pressure of the springs in the negative.

- Exact torque regulation through a balanced radial nut;

- Innovative calibration system by quote “H“ for an immediate calibration of the device;

- Re-engagement in equidistant phase (DSS/SG) or 360° (DSS/F/SG);

- Maintenance free;

- Possibility to add a microswitch / proximity to stop the motor drive;

- Model available only with finished bore;

- Drive component assembled and directly supported by a ball bearing.

- Complete with transmission component worked and assembled (plate wheel, pulley, gear,…);

- Available in stainless steel for food and pharmaceutical environments;

- Possibility to have a connection flange to the most common intermittent drive units;

- Feasibility in personalized phase at 30°, 45°, 60°, 90°, …

- Print machines and packaging machines;

- CNC tool machines;

- Index tables, filling machines, guiders;

- Servomotors, slide guides.

- To protect the product against faulty positioning on the rotating table;

- To protect the indexing against overloading along the transmission;

- To protect the operating units of machine tools against impacts;

- To protect slides or servomotors against impact or limit stops.

Positive version ".../P"

- Angular backlash free;

- Maximum simplicity of calibration by standard method;

- Wide regulation torque range;

- Very fast response times;

- Available with extended hub to assemble wide drive components: …/ML;

- Torque ranges: 2 – 750 Nm; max. bore: ø65 mm.

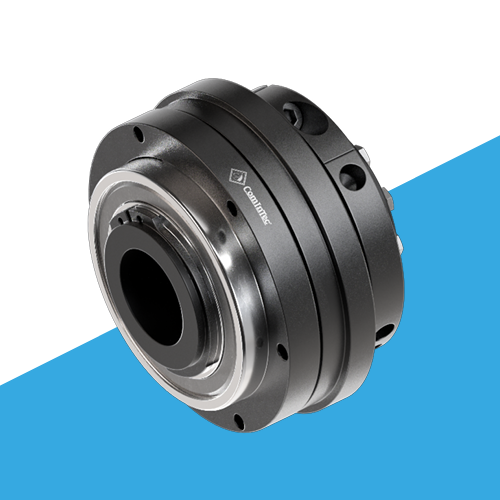

Negative version ".../N"

- Angular backlash free with compact dimensions;

- Instantaneous torque transmission reduction when overloading;

- Free of residual torque after disengagement;

- Fastest response times and highest sensitivity;

- Available with extended hub to assemble wide drive components: …/ML;

- Torque range: 0,6 – 720 Nm; max. bore ø65 mm.

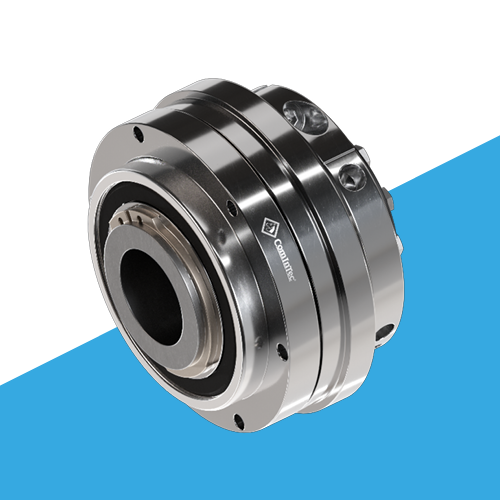

Stainless steel version "DSS/SG"

- Model without any backlash;

- Same dimensions as the standard model, both in negative and positive versions;

- Made in stainless steel at high resistance by suitable heat treatments;

- High resistance to corrosion;

- Suitable to food and/or pharmaceutical environments;

- Torque range: 1,5 to 900 Nm; maximum bore ø65 m.

Electromechanical switch "EM"

- Die-cast aluminium box;

- Protection level IP57 DIN 40050;

- Possibility of 1 contact (EM1) or 2 contacts (EM2) available;

- Adjustment of the lever end position possible;

- Operation temperature range from -10°C to +85°C;

- Three different options of voltage input: 1,5A – 250 VCA; 5A-24 VCC; 0,2A-250 VdC;

- Initial stroke 0,7 mm, Extra stroke: 4 ÷ 8 mm depending on setting (possible in a range of 6 mm).

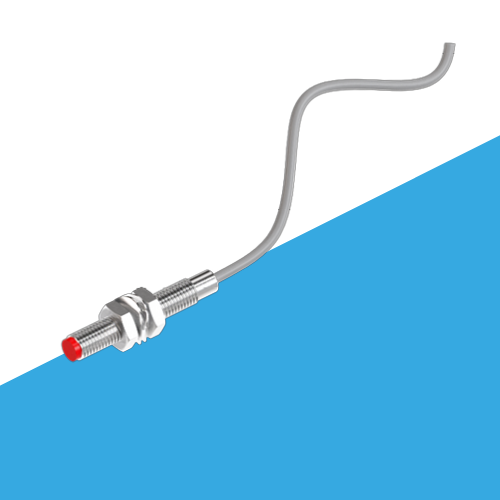

Proximity sensor "PRX"

- Standard version: Stainless steel cover with protection level IP67 DIN 40050;

- Electric contact: 7 ÷ 30 VdC. – Frequency: 4 KHz; Absorption ≤ 10 mA (Max 200mA);

- Output: NPN (N.O.-N.C.) – PNP (N.O.-N.C.);

- Operating distance: max 1,5 mm;

- Cable length: 2 m (3×0,2);

- Operation temperature range from -25°C to + 70°C.